Silicon nitride ceramics are crystal structures composed of silicon (Si) and nitrogen (N) atoms and are highly engineered materials. It has unique comprehensive properties including high strength, excellent thermal stability, super wear resistance and excellent corrosion resistance, etc., and has been widely concerned in all walks of life because of its excellent performance.

The production of #silicon nitride ceramics mainly includes various shapes of silicon nitride ceramics machined parts, silicon nitride ceramic substrates and their extended substrates metallized to meet the needs of specific applications in various industrial links.

1. Silicon nitride ceramic structure

1.1. Silicon nitride ceramic bearings:

#Silicon nitride bearings are widely used in mechanical systems requiring high speed and high temperature operation. Compared with traditional materials, silicon nitride bearings can effectively reduce friction and wear, extend service life and improve efficiency.

1.2. Silicon nitride cutting tools:

Silicon nitride cutting tools are known for their superior hardness and heat resistance. #Silicon nitride tools are widely used in metal processing such as milling, turning and drilling to provide high precision machining and extend tool life.

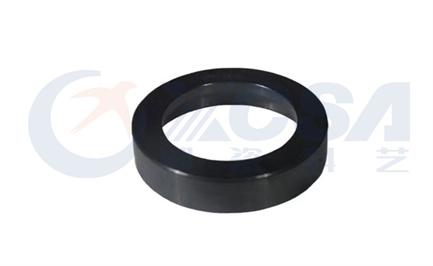

1.3. Silicon nitride seals and components:

Silicon nitride seals and components are used in harsh environments that require excellent chemical resistance and high temperature resistance. They are used in industries such as aerospace, automotive and chemical processing.

1.4 Silicon nitride ceramic parts for solar energy applications

Mainly used in polycrystalline silicon reduction furnace electrode inside and outside insulation ring, insulation sleeve, heat insulation ring, heat insulation sleeve, tail gas cover and thermocouple protection tube.

2. Silicon nitride ceramic substrate and AMB (Active Metal Bonding) process:

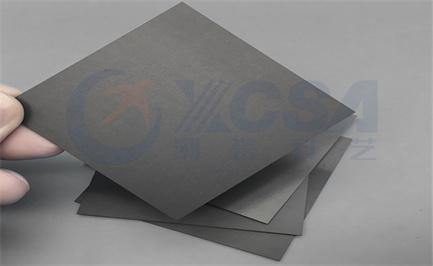

2.1. Substrate manufacturing:

The preparation of silicon nitride ceramic substrate combines powder processing, molding and sintering technology. This results in a dense, robust substrate with excellent electrical and thermal properties.

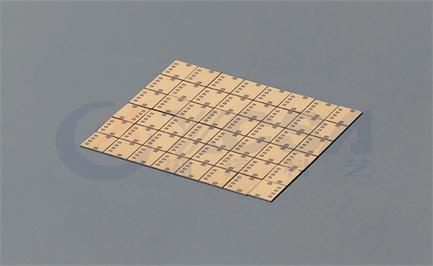

2.2 Silicon nitride AMB (Active Metal Bonding)

Compared with DBC ceramic substrate, #AMB ceramic substrate has higher bonding strength and hot and cold cycling characteristics. At present, with the rapid development of power electronics technology, the high-power device control module on high-speed rail has formed a huge demand for the key material of IGBT module packaging - ceramic copper clad plate, especially the silicon nitride AMB substrate has gradually become the mainstream application. In addition, in wind energy, solar energy, heat pump, hydropower, biomass energy, green building, new energy equipment, electric vehicles, rail transit and other important fields, AMB substrate has also begun to get more and more applications.

Conclusion

Silicon nitride ceramics have unique properties and a wide range of applications and have become an important material in many industries. Paving the way for technological advances in fields ranging from electronics to aerospace.

Xiang Ceramics specializes in the production of silicon nitride ceramic balls, silicon nitride ceramic machined parts, silicon nitride ceramic bare pieces and AMB pieces, and provides product customization services. If you have any demand for the product, please send your questions or consultation information to us through the following contact ways.

Email: joicetse@xcsawork.com

WhatsApp / Mobile: 0086+15616337419

WeChat: joicetse

Skype: Joice.tse