#Aluminum Nitride ceramic is a new type of ceramic material with excellent comprehensive properties, with excellent thermal conductivity, reliable electrical insulation, low dielectric constant and dielectric loss, non-toxic and silicon matching thermal expansion coefficient and a series of excellent characteristics, is considered to be a new generation of highly integrated semiconductor substrate and electronic devices ideal packaging materials. In addition, aluminum nitride ceramics can be used as crucible for melting non-ferrous metals and semiconductor materials gallium arsenide, evaporation boat, thermocouple protection tube, high temperature insulation parts, and can be used as high temperature corrosion resistant structural ceramics, transparent aluminum nitride ceramic products, so it has become a kind of inorganic materials with wide application prospects.

From aluminum nitride powder to various aluminum nitride ceramic shaped parts, aluminum nitride mechanical arms for semiconductor equipment, #aluminum nitride ceramic heaters for semiconductor equipment, aluminum nitride ceramic substrates and their extended DBC, DPC, AMB and HTCC, Xiang Ceramics has strong technical and production advantages. Our main aluminum nitride product categories and application areas are as follows:

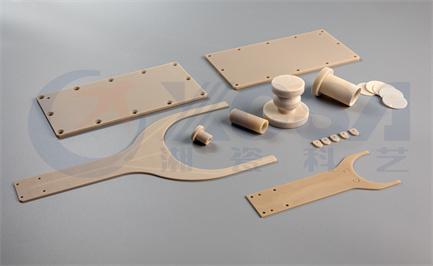

1. AIN Ceramic Machined parts

Because of its excellent hardness and wear resistance, aluminum nitride ceramics are widely used in machining parts manufacturing in all walks of life. However, the precision processing difficulty of aluminum nitride ceramic materials is actually relatively large, mainly because aluminum nitride ceramics have two kinds of brittle and hard material characteristics, so it causes great trouble to CNC machining, and it is necessary to use ceramic special engraving and milling machine to process aluminum nitride ceramics. Xiang Ceramics is equipped with a number of high-end ceramic machining equipment, the product processing precision is high, recognized by the majority of customers. In addition, these aluminum nitride ceramic components can be used in cutting tools, wear parts and high temperature furnace fixtures. The high thermal conductivity of aluminum nitride ceramics ensures efficient heat dissipation and is therefore suitable for demanding applications.

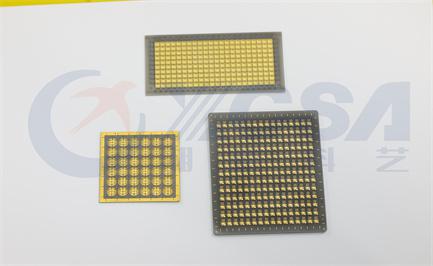

2. AIN Substrates / AIN Sheets / AIN Plates

2.1 Aluminum nitride ceramic substrate has excellent thermal conductivity, thermal expansion coefficient close to silicon, high mechanical strength, good chemical stability and environmental protection and non-toxic, is considered to be a new generation of thermal substrate and electronic device packaging ideal material, very suitable for mixed power switch packaging and microwave vacuum tube package shell material, but also the ideal material for large-scale integrated circuit substrate. This is also the main use of #AlN ceramic substrates.

2.2 Aluminum nitride ceramic substrate and its extension process

a. Direct bonding copper (DBC): DBC technology uses a metallization process to bond aluminum nitride ceramics to copper. This composite material combines the excellent properties of aluminum nitride ceramics with the high electrical and thermal conductivity of copper. #DBC substrates are widely used in power electronic devices such as insulated gate bipolar transistors (IGBTs) and high-power diodes.

b. Direct Copper plating (DPC): The DPC Substrate is similar to the DBC substrate but uses different bonding techniques. DPC technology is the direct plating of copper on the surface of aluminum nitride ceramics. This process does not require a separate metallization step. The DPC substrate has better thermal management and electrical performance, making it suitable for high-power applications.

c. AMB: AMB (Active Metal Brazing) active brazing technology is a process technology in which Ag-based solder containing active elements Ti and Zr is wetted and reacted at the interface of ceramics and metals at a high temperature of about 800℃, so as to achieve heterogeneous bonding between ceramics and metals. Aluminum nitride ceramic substrates are also widely used in IGBT modules of new energy vehicles.

d. High temperature co-fired ceramics (HTCC): HTCC is a multi-layer ceramic technology that combines aluminum nitride ceramics with other functional materials such as resistors, capacitors and conductors. HTCC substrates undergo a series of printing, stacking and co-firing processes to form complex integrated circuits. These substrates have excellent electrical properties and are widely used in high frequency and high-power applications.

Conclusion

Aluminum nitride ceramics are widely used in various industries for their excellent properties, and the introduction of machined parts, substrates and extension processes (such as DBC, DPC, AMB and HTCC, etc.) has expanded the application range of aluminum nitride ceramics. Ongoing research and development in this area will continue to open up new possibilities. If you need to know more product details, please contact us through the following ways.

Email: joicetse@xcsawork.com

WhatsApp / Mobile: 0086+15616337419

WeChat: joicetse

Skype: Joice.tse